Version scale from gauge [bar] |

0 - 600 |

|||

Weight (kg) |

1.960 |

|||

Capacity cylinder (cm3) |

400 |

|||

Cylinder external dia. (mm) |

58 |

|||

Cylinder lenght (mm) |

300 |

|||

Cylinder wall thickness (mm) |

1.5 |

|||

Filling with grease cartridge 400g DIN 1284 |

YES |

|||

Filling with filler pump |

NO |

|||

Min. / Max. temperature (°C) |

10 /40 |

|||

Specification for operation medium |

Lubricants up to NLGI 3 / 5000 m Pa.s |

|||

Operating pressure (bar) |

450 |

|||

Max. pressure (bar) |

600 |

|||

Delivery rate pro stroke (cm3) |

0.3 |

|||

Connection (medium) internal thread P |

1/8" BSP |

|||

Connection (air vent) internal thread E |

M8 x 1 |

|||

Connection (gauge) internal thread M |

1/4" BSP |

|||

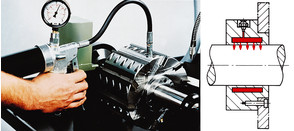

High Pressure One-hand pump with >Gauge is used for clamping tools and face milling gutters

More

and more face milling cutters and declamping tools are hydraulically

clamped.

An

implemented pressroom in the tool is put under pressure through grease

or oil,

so that the tool as example is pressed onto the shaft of the machine.

|

This

kind of tension enables transferring high torque |

|

Important Information

The

temperature has a high influence on setting the pressure to the

clamping unit

and on the choice of the high pressure one-hand pump.

If

the temperature falls, pressure also drops, and vice versa. Differences

in temperature of more than 30°C

will most probably require a further setting of the pressure to the

clamping unit. Regular controls have to be done.

Character features of High Pressure One-hand Pump:

- Ergonomic plastic handle for comfortable and simple handling

- Controlled and accurate application, due to check valve, air bleed valve and pressure release valve

- Generates high clamping force without ancillary power

- Easy and clean disconnection of nipple due to pressure release valve and lubricant return flow to the cylinder

- The pressure gauge serves as control tool for clamping or precise controlled pressure build-up for tool chucks