Catalog

OIL DRIPPERS

|

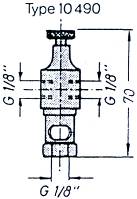

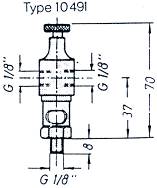

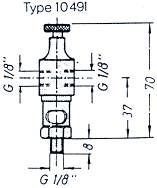

Type ETR 10490/10491, pickled brass

Turned design of

solid brass - with metering spindle for the exact drop dosing

- easy visual inspection of drop fall - inspection glass

of »PLEXIGLAS« or natural glass. These UNI drip feed

lubricators can be used universally, e.g. in building

machinery, agricultural machines, conveying and transport

equipment as well as in all sections of the general machinebuilding

industry. With the UNI drip feed lubricators MOS (electrically

controlled) automatic central lubrication systems can be

combined for any application. It is also possible to feed

the lubricant to the drip feed lubricators through the

circuit of a gear pump.

For the simultaneous supply of several lubricating points, the UNI drip feed lubricators ETR can be connected in one supply line one behind the other. The metering spindles permit an dosing for each lubricating point to be supplied. The lubrication equipment structured in this way is centrally switched on and off through the connected oil dispenser. |

|

||

|

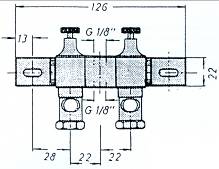

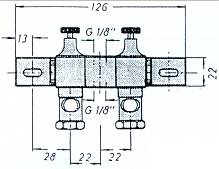

Type MTR 1-10, pickled brassUNI drip feed lubricators MTR are batteries composed of individual drip feed lubricators with lateral angle brackets. Metering spindles permit the exact drop dosing at each individual drip feed lubricator. The drop fall can easily be observed by the installed inspection glasses. In combination with the oil dispensers MOS (manual), EOS (electrically controlled) or supplied by a gear pump, universal central lubrication systems can be built.Combined with UNI oil dispensers and UNI lubricating brushes SPR (round) / SPF (flat), lubricating and maintenance units are obtained for the lubrication of chains, conveyors, slide ways and metal ropes, that have many times stood their test. |

Contact

Brands