Grease nipples

HYDRAULIC-TYPE GREASE NIPPLES

HYDRAULIC GREASE NIPPLES WITH SELF-FORMING THREAD

HYDRAULIC-TYPE GREASE NIPPLES - DRIVE-IN VERSION

HYDRAULIC-TYPE GREASE NIPPLES - SPECIAL DESIGNS

ALL-TYPE GREASE NIPPLES ACCORDING TO FORMER DIN 3402

BALL-TYPE GREASE NIPPLES - DRIVE-IN VERSION APPLICATION AREA

FLUSH-TYPE GREASE NIPPLES ACCORDING TO DIN 3405

FLUSH-TYPE GREASE NIPPLES

FLUSH-TYPE GREASE NIPPLES - DRIVE-IN VERSION

FLUSH-TYPE GREASE NIPPLES - SPECIAL DESIGNS VERSIONS

BUTTON-HEAD GREASE NIPPLES

BUTTON-HEAD GREASE NIPPLES

BAYONET GREASE NIPPLES

GREASE NIPPLES ASSORTMENTS

PROTECTIVE CAPS

Grease Nipples

Maintaining permanent motion!

They are small and inconspicuous, but responsible for keeping machines and all kinds of equipment in motion - whether in a harvester in Russia, a pipeline in Alaska, or a brewery in Australia. There is a UMETA Grease Nipple for every application purpose in most sizes, types and composition. With a range of more than 1,500 different types of nipples with about 70 different thread forms, we offer the largest product line worldwide.

Depending on the application and the installation sites, we can manufacture grease nipple according to international standards. Other than a standard version made of steel, zinc-plated and passivated, we offer many other types, made of brass or stainless steel. You will always find a solution in our range of products - even for the most challenging application. Rely on us - since we are manufacturer and not a dealer - for about 80 years!

UMETA GREASE NIPPLES - ADVANTAGES AT A GLANCE

- 1,500 available types

- hydraulic-type-, ball-type-, flush-type-, bayonet-, and button-head nipples

- standard versions made of zinc-plated steel,

- stainless steel, or brass

- case-hardened according to DIN

- international product standards

- (e. g. DIN, ISO, SAE, BS, JIS)

- individual, custom-designed solutions

- individual packaging according to customers requirements

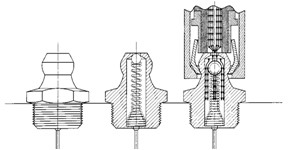

FUNCTION OF A GREASE NIPPLE

TASKS OF A GREASE NIPPLE

- protection of the lubrication point against dirt and humidity – no sealing against internal pressure

- standardized connection to the grease gun

- essential for maintenance and repairs

RANGE OF APPLICATIONS

- bearings

- hinges for machines, vehicles, industry

- cardan shafts

- drive shafts

- linear guides

- hydraulic cylinders

- drives

- chains

- axels

GREASE NIPPLES ARE MANUFACTURED OF

- steel: 1.0718 (11SMnPb30+C) SAE 12L13

- stainless steel: 1.4305 ~ ASTM303 (SST303);

- 1.4401, 1.4404 ~ ASTM316, 316L (SST316L)

- brass: CuZn39 Pb3 (CW614N)

APPLICATION AREA

UMETA hydraulic-type nipples are suitable for all standard lubrication points, which have to be frequently lubricated in a reliably way. Due to their multi-purpose field of application, they are the most commonly used types of grease nipples.

VERSIONS

In general, our hydraulic-type grease nipples according to DIN are made of steel, case-hardened, zinc-plated and passivated, and they are featured with a tapered thread. The head diameter is 6.5 (-0.2) mm / 0.256" (- 0.008"). For safety reasons and in order to avoid abrasion wear, the standard demands 550 HV as a minimum for a surface hardness. Therefore, we operate this decisive process in our own curing oven. We offer various standard types also in brass or stainless steel 1.4305 ~ ASTM 303 and 1.4404 ~ ASTM 316L (V2A/V4A). Of course, our hydraulictype nipples are also available in different angle versions, with a self-forming thread, or as drive-in type.

SPECIAL VERSIONS

Upon request, UMETA manufactures hydraulic-type nipples in other versions, with respect to the following:

- dimension

- material

- thread size

- thread form (e. g. with cylindrical thread)

- opening pressure

- surface colour (e. g. yellow passivated)

- further surface treatment

- unhardened

- etc.

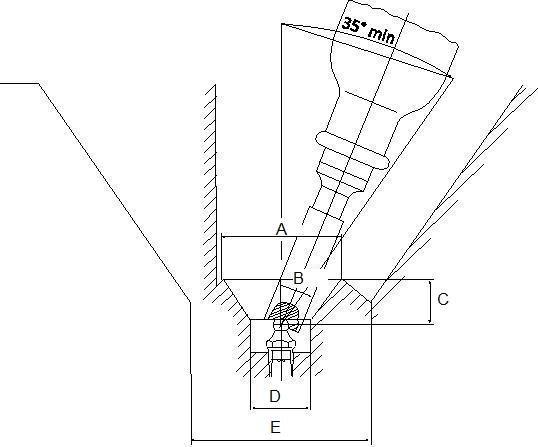

| Head space | |||

|---|---|---|---|

| A= | 50mm(1.97") | D= | 25mm(0.98"-63/64") |

| B= | 16.5mm(0.65") | E= | 75mm(3") |

| C= | 19mm(0.75"-3/4") | F= | 55mm(2.16"-2.125") |

MOUNTING INSTRUCTIONS

In order to allow for a proper lubrication with all common grease guns, the head space, which is necessary for installation, should be considered (please see table with dimensions).

OPERATING INSTRUCTIONS

As suitable lubricating nozzle, we recommend our hydraulic couplers.