FLUSH-TYPE GREASE NIPPLES

FLUSH-TYPE GREASE NIPPLES WITH SELF-FORMING THREAD

APPLICATION AREA

By using UMETA grease nipples with self-forming thread (SFT / SFG) you effectively save the thread-cutting process in the borehole.

VERSIONS

For safety reasons and in order to avoid abrasion wear, the DIN standard for grease nipples with self-forming thread demands a specific surface hardness of 650 HV minimum as well as a particularly wide flank angle of 105° at the thread. Therefore, we operate this decisive process in our own curing oven. For a better visual distinction, UMETA self-forming grease nipples are yellow passivated. Upon request, they are also available in another surface colour, e. g. blue passivated = silver coloured.

MOUNTING INSTRUCTIONS

The special thread angle and the specific hardness level allow these grease nipples to be driven and screwed into holes without prior thread cutting. Thus, the thread of the grease nipple forms its counter thread. Later, the grease nipple can easily be screwed out and be replaced by a standard grease nipple. The exact size of the core hole depends on the material and must be determined by mounting tests. The consistency of the receiving material is decisive.The standard gauge for the installation bore diameter of 0.4-0.5 mm (0.02") below nominal width have proved in daily use.

OPERATING INSTRUCTIONS

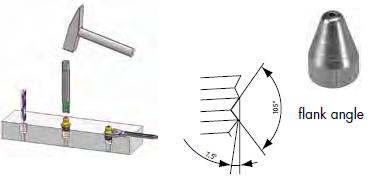

As suitable lubricating nozzle, we recommend our pointed nozzles.